Investigation of uniform and gradient octet lattice structure mechanical properties

September 2023 to November 2023 - Dartmouth College

Injuries from Resistance Training:

Resistance training, which consists of lifting weights to improve strength and endurance, is a popular fitness pastime with about 30% of Americans engaging in strength training regularly [2]. The National Electronic Injury Surveillance System reported an estimated 980,173 injuries nationwide per year caused by weight training activity or equipment. While the number of injuries due to the barbell bar itself is unclear, this piece of equipment is known to cause bruising, scraping, and pinching of the skin.

The barbell pad is made of a high-density industrial grade foam rubber (such as nitrile butadiene rubber foam, polyethylene foam, and other open cell materials) and manufactured by extrusion techniques. It has historically been utilized to prevent injuries from exercises like the barbell squat and hip thrust by distributing the barbell’s weight and additional load evenly across the shoulders or hips, respectively (See Figure 1). The main drawbacks of this kind of material are that it does not have a high compression life cycle, it is not resilient, and it is prone to permanent deformation after repeated loading and unloading.

Advantages of Additively Manufactured Lattice Structures:

Additively manufactured (ADM) lattice structures, conversely, have been shown to possess better material properties, including compressive response, thermal insulation, and noise suppression, compared to conventional foam [1], [3], [4]. One such example is the design of unit cell geometries to construct specialized support structures for alleviating pressure ulcers, a significant source of patient discomfort and morbidity in the healthcare setting, leading to improved outcomes for rehabilitation cushions owing to the greater airflow, diminished expense, and simplified manufacturing process [3]. Preliminary studies have demonstrated the potential application of ADM lattice structures for energy absorption in conformal body protection as well [4].

A comprehensive review paper discussed the energy absorption properties of 2D and 3D lattice structures and found that under uniaxial quasi-static compression, octet structures had high specific strength and were able to replace metal foam [5]. Another study discovered that the mechanical characteristics of another octet structure that underwent both uniaxial quasi static and dynamic compressive loading were correlated to the relative density of the structure, and that the specific energy absorption increased in relation to relative density and was significantly higher than the traditional honeycomb structure [6], [7].

The literature had a few conflicting conclusions regarding gradient architectures [8]. Lattices with BCC gradient geometry absorbed slightly more energy than the homogeneous BCC geometry before densification [9], while the plastic plateau and energy absorption of the functionally gradient double pyramid dodecahedron models were lower than the uniform model [10] after undergoing uniaxial quasi- static compression. Another experiment agreed that the gradient structure of gyroid cellular structure had larger strain protection and high energy absorption capacity prior to densification than the uniform structure [11]. Therefore, it would be interesting to test the effectiveness of the homogeneous octet unit lattice arrangement when compared to the gradient octet lattice arrangement.

Taking a look at the patent landscape to get a clearer picture of the materials and technology utilized for barbell pads that are commercially available, there are two in total: one outlining an innovation in the material used and another detailing a fastening method. The former proposes a granular ethylene vinyl acetate made by an injection molding process that increases the surface area of the pad to provide greater comfort and control for the end user than the straight tubular pads. The novel ogee curvature can more closely conform to the human body and the closed cell foam material is favorable for minimal compression and longer useable lifespan [12]. However, there was no finite element analysis (FEA), compressive testing, or other method of evaluation of the material reported. This gap in the field offers great potential for innovation in the patent domain.

Project Objectives & Methodology:

Design lattice structure for a 3D-printed barbell bolster that is able to withstand the largest compressive force with minimal fracturing and permanent deformation. The project assesses the theoretical and experimental behavior of the design with varying parameters for the geometry of the unit cell - gradient versus uniform - and evaluates the best combination of aforementioned parameters.

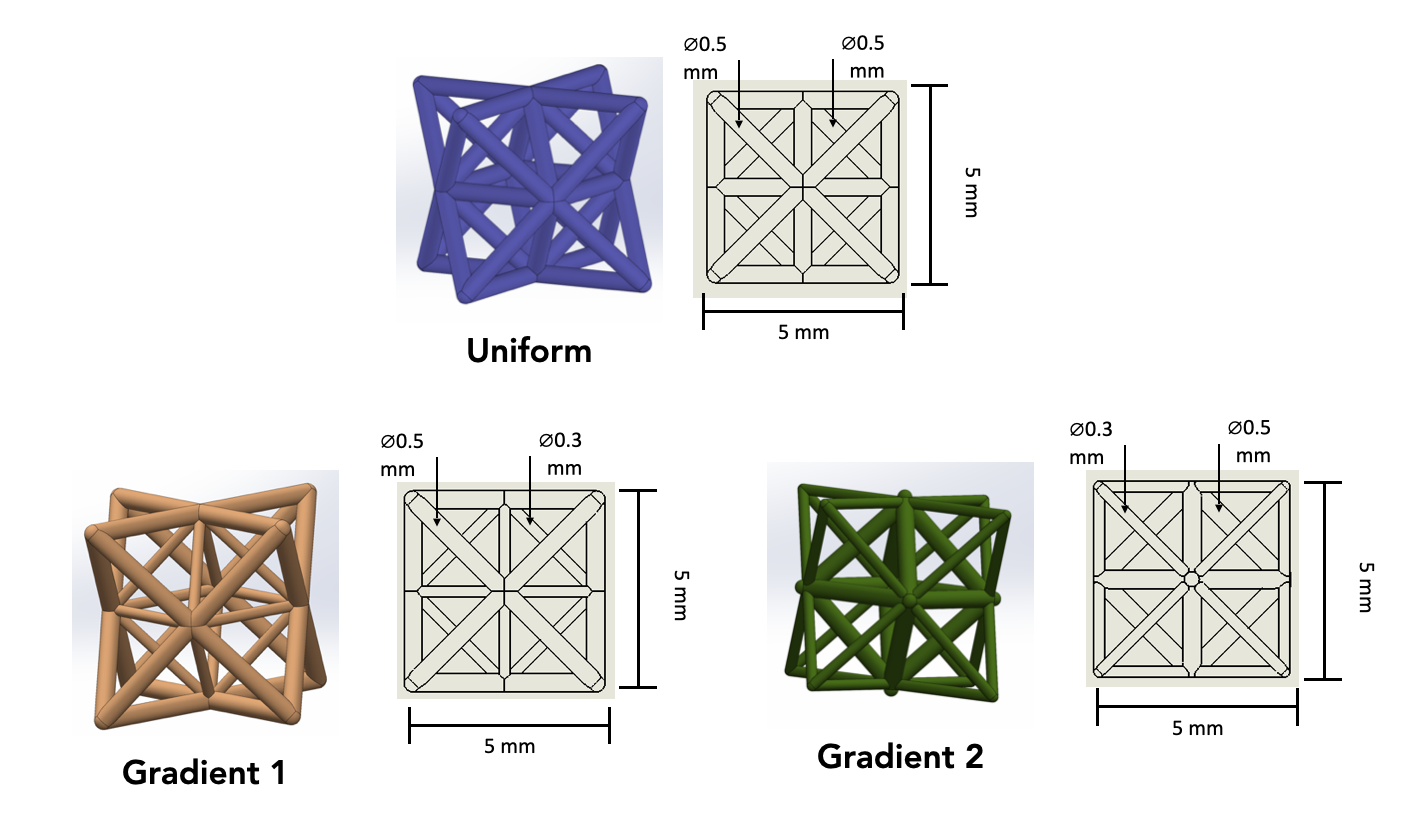

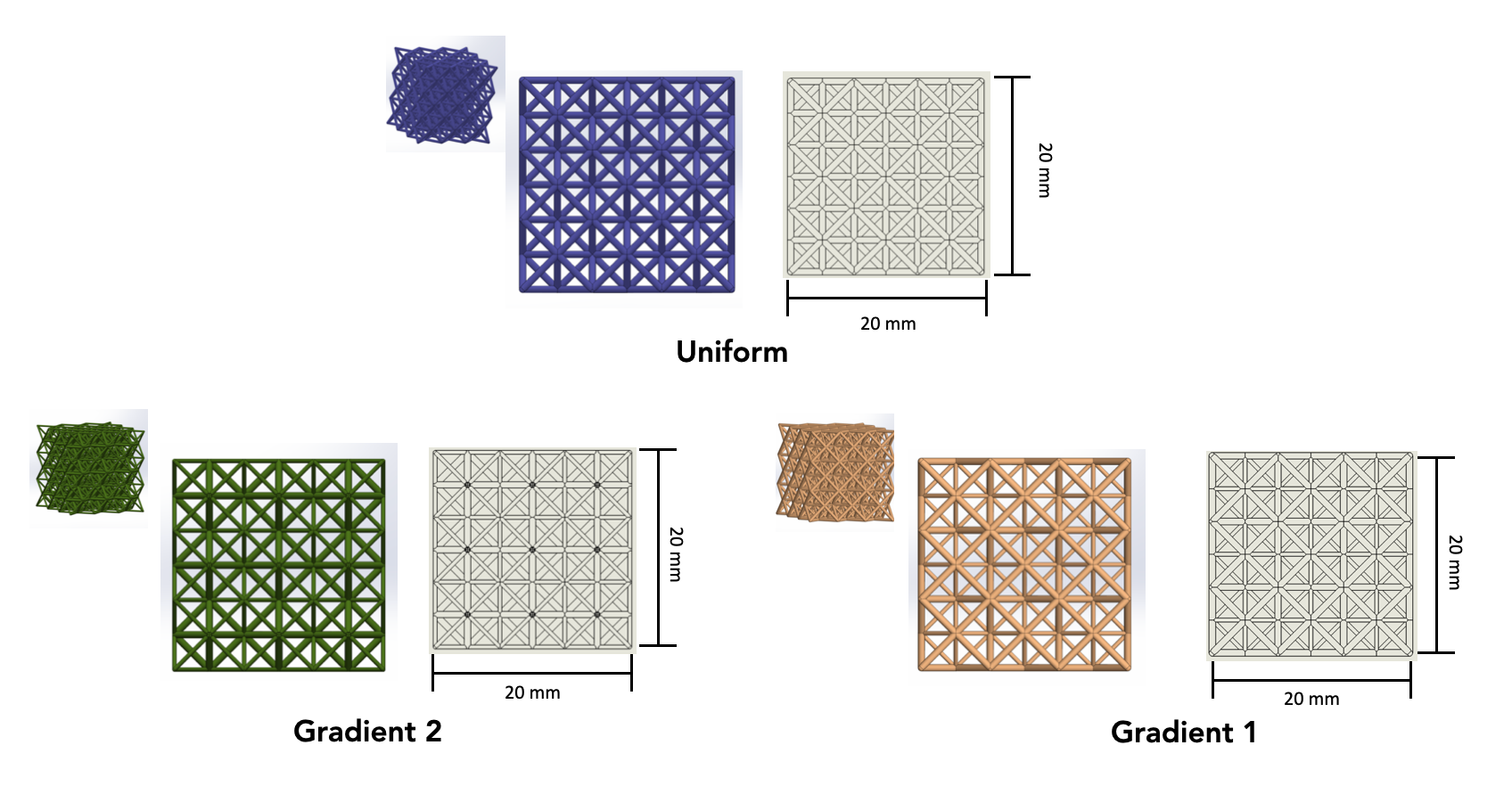

The chosen parameters to vary in the Octet lattice structure are the truss (or strut) sizes, thereby comparing a homogenous lattice cube to two gradient, or non-uniform, structures. The unit cell refers to the smallest repeating and structurally self-contained element that makes up the lattice, while the lattice structure or cube repeating and regular three-dimensional arrangement of said unit cells.

The set up for the simulated compression test involved setting the bottom platen as a fixed entity, applying a load on the top platen, and creating a curvature-based mesh. Once the mesh was created, the study was run multiple times with varying loads in increasing magnitude.

Once the design variations have been made in SolidWorks they will be printed on the SLA FormLabs Form 3B+ machine by curing layers of liquid resin via a ultra-violet light source. The successfully printed structures will undergo compression testing on the Instron 4469 machine. Finally, the predicted values will be compared to the tested values and conclusions will be drawn about possible design approaches to improve the load bearing capability of the lattice structures.

Results & Discussion:

The Gradient II lattice cube design with thinner inner unit cell struts and thicker outer unit cell struts did not perform well, whereas the Gradient I had design had potential for withstanding higher loads but with larger diameters such as that of the Uniform model. Some recommendations for design variations to improve the structure’s performance include defining thicker exterior struts in the unit cell, which should be at least 0.5 mm thick. In the future, it may be worthwhile to explore the potential benefit of increasing the thickness of the struts specifically on the outer faces of the cubes, particularly those in direct contact with the platens.

References:

[1] B. K. Nagesha, V. Dhinakaran, M. Varsha Shree, K. P. Manoj Kumar, D. Chalawadi, and T. Sathish, “Review on characterization and impacts of the lattice structure in additive manufacturing,” Materials Today: Proceedings, vol. 21, pp. 916–919, 2020, doi: 10.1016/j.matpr.2019.08.158.

[2] J. A. Bennie et al., “Muscle-Strengthening Exercise Among 397,423 U.S. Adults: Prevalence, Correlates, and Associations With Health Conditions,” American Journal of Preventive Medicine, vol. 55, no. 6, pp. 864–874, Dec. 2018, doi: 10.1016/j.amepre.2018.07.022.

[3] D. W. Holmes et al., “Mechanical behaviour of flexible 3D printed gyroid structures as a tuneable replacement for soft padding foam,” Additive Manufacturing, vol. 50, p. 102555, Feb. 2022, doi: 10.1016/j.addma.2021.102555.

[4] J. Brennan-Craddock, D. Brackett, R. Wildman, and R. Hague, “The design of impact absorbing structures for additive manufacture,” J. Phys.: Conf. Ser., vol. 382, p. 012042, Aug. 2012, doi: 10.1088/1742-6596/382/1/012042.

[5] V. S. Deshpande, N. A. Fleck, and M. F. Ashby, “E ective properties of the octet-truss lattice material,” J. Mech. Phys. Solids, 2001.

[6] T. Tancogne-Dejean, A. B. Spierings, and D. Mohr, “Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading,” Acta Materialia, vol. 116, pp. 14–28, Sep. 2016, doi: 10.1016/j.actamat.2016.05.054.

[7] C. Ling, A. Cernicchi, M. D. Gilchrist, and P. Cardiff, “Mechanical behaviour of additively- manufactured polymeric octet-truss lattice structures under quasi-static and dynamic compressive loading,” Materials & Design, vol. 162, pp. 106–118, Jan. 2019, doi: 10.1016/j.matdes.2018.11.035.

[8] H. Yin, W. Zhang, L. Zhu, F. Meng, J. Liu, and G. Wen, “Review on lattice structures for energy absorption properties,” Composite Structures, vol. 304, p. 116397, Jan. 2023, doi: 10.1016/j.compstruct.2022.116397.

[9] I. Maskery et al., “A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting,” Materials Science and Engineering: A, vol. 670, pp. 264– 274, Jul. 2016, doi: 10.1016/j.msea.2016.06.013.

[10]M. Mahbod and M. Asgari, “Elastic and plastic characterization of a new developed additively manufactured functionally graded porous lattice structure: Analytical and numerical models,” International Journal of Mechanical Sciences, vol. 155, pp. 248–266, May 2019, doi: 10.1016/j.ijmecsci.2019.02.041.

[11] L. Yang, R. Mertens, M. Ferrucci, C. Yan, Y. Shi, and S. Yang, “Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties,” Materials & Design, vol. 162, pp. 394–404, Jan. 2019, doi: 10.1016/j.matdes.2018.12.007.

[12]A. Carpinelli, E. M. Layus, and K. S. Wolff, “INJECTION MOLDED EVA FOAM BARBELL PAD.” EP 3 275 509 A1, Jan. 31, 2018.